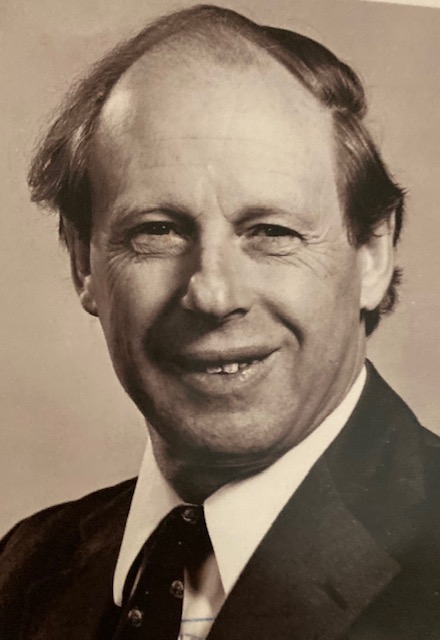

IN MEMORY OF TREVOR KLETZ

by Jacqueline Ward on Tuesday, 28th March 2023 at 3:11pm

A centenary tribute highlighting some of Trevor’s work on improving process safety

In 1968, having spent 16 years in production, including a short spell in process design, Trevor was appointed ICI’s first technical safety adviser to the Heavy Organic Chemicals (HOC) later Petrochemicals, Division. Following ten years in which HOC’s fatal accident rate had worsened his responsibility was to improve process safety. He often said this was “by accident”. He though proved to have been the right person at the right time in the right place.

Although he was an “adviser” he was expected to decide what should be done to improve process safety and to see that it happened. Those decisions were by necessity based on thorough investigations. It was clear that existing attitudes and practices in ICI, and in other companies, would need a considerable shift. It was recognised that this might take a long time. Those who were in his team, some for many years, had the good fortune to take part in making history. Together they caused a radical change in attitudes and practices in process safety leading to a lasting improvement in safety performance. Contemporaries had the benefit of gaining access to that important and innovative work.

Trevor considered that speaking and writing about his work, at every opportunity, was the best way forward. He was fortunate in that the ICI culture at this time allowed people enough personal freedom to do what needed to be done. He described his motivation as:

- Everyone going to work should reasonably expect to return home safely.

- Accidents keep happening and recurring because learning from experience was not applied to prevention.

- Safety information should be spread widely across industry.

- Change is more likely to happen if people convince themselves of the reasons why it is needed, and know what they have to do to implement it.

To set about improving process safety he decided that it was necessary to probe incident experience more deeply, to expose the fundamental reasons for failures. This knowledge could then be used to minimise loss by better design of plant, process and operating practice. The latter based on a better understanding of why people erred.

Trevor was a born communicator. He always spoke patiently and simply. He had a modest yet impressive presence. He thought clearly. He was persuasive. He used sound reasoning to explain his ideas. He used these attributes when speaking and in his writings. What he said was always relevant to his listeners or readers. He had an ability in conversation and writing, to highlight an insight into incident experience which others had missed. Often the reaction was “oh, that’s common sense”, and it was; but it had not previously been recognised as such. To strengthen the memory of his conversations or writings, he would often make a succinct remark. Many of these have passed into common use. For example, when referring to potential leaks from a large inventory of flammable liquid he would say, “What you don’t have can’t leak”. These remarks caught the imagination and were remembered. It wasn’t only his remarks but his actions that caught the imagination. Trevor wearing his red braces and a belt to demonstrate the benefits of diversity is widely recalled.

For many years he arranged multi-disciplinary weekly morning meeting to discuss incidents from the Company and elsewhere. Each incident was introduced briefly and participants invited to say what they thought should be done. This method of learning helped to change attitudes to process safety. The notes and the accompanying slides were assembled into themes and made available (as Hazard Workshop Modules) for any line manager to use with his team. At a later date a group of them was passed to the I Chem E. There they were used by the Loss Prevention Panel in developing its programme of training courses in process safety. Subsequently details of an in-company course on the principles of process safety were passed to the Institution to enhance its training programme. Through external interest it was also presented publicly and made known to other companies.

For people who could not attend these weekly gatherings nor have a conversation with Trevor or his colleagues, a monthly safety newsletter was started. Each of these described a few incidents usually reflecting a theme. The style followed the pattern of the weekly discussions. Each issue usually had an apt illustration by a professional artist. In 1968 the first edition was circulated to about 30 colleagues. Gradually over the next 14 years the circulation and contents grew to several thousand. It was sent to the various divisions in ICI, and to other companies, universities and the Health and Safety Executive. The newsletters were not intended primarily for “safety professionals” but for those involved in design, operation and maintenance. As well as the newsletter a calendar was issued every year. Each month had a professionally produced cartoon illustrating some aspect of loss prevention. These activities resulted in improvements in the understanding of loss prevention.

Trevor recognised the ICI contribution to this knowledge sharing. According to him they allowed him to share reports on their errors all over the world for four reasons:

- Moral: if you have information which may prevent accidents there is a moral duty to pass it on to other people.

- Economic: ICI spent a lot of money on safety. By telling their competitors what they did they encouraged them to spend as much.

- Pragmatic: they got useful information in return.

- In the eyes of the public, the chemical industry is one. The whole industry suffers if one part performs badly.

In his book “By Accident”, Trevor describes his career in his usual clear and succinct manner. It is a worthwhile read for anyone who works in process safety. The book finishes with a table, “What I Did and Why I Did It”; subtitled “My main interests in Loss Prevention and what triggered them”. That table is a template for making improvements in process safety and minimising loss. It can be used as a guideline for anyone who wishes to improve process safety.

He and fellow author Paul Amyotte, in their handbook “Process Plants” made clear their advocacy of “Inherently Safer Plants”. Inherently safer plants can be achieved by:

- Using smaller inventories of hazardous materials.

- Substituting hazardous with less hazardous materials.

- Using less hazardous conditions (e.g. lower temperatures or low pressures).

- Minimising the impact of any operational failure.

Others knew that such actions would reduce process risks but nobody had previously explained that practice of plant design so completely and succinctly.

Trevor recognised the need to obtain better information to aid risk reduction. This included how to estimate the scale of damage from a hazardous event. As a result investigations were carried out to provide guidance on, for example, how far gas and flammable liquid releases would spread, how they might be dispersed and the spacing of plants – against domino effects. Guidance was prepared, for example, on procedures for plant and process modifications, choice of electrical equipment in likely flammable atmospheres and fire protection measures.

Trevor was involved in the development of the use of HAZOP and HAZAN to examine project engineering designs. He was not only an innovator but a developer of other peoples’ ideas. As he points out in his book “By Accident”, HAZOP was developed from the application of “Critical Analysis” of plant design by others in ICI. Later in his role as safety adviser he was a keen advocate of HAZOP. His enthusiasm for applying this logical approach to the detail of plant design undoubtedly helped in it becoming widely adopted and developed.

Trevor recognised the benefit of using numerical methods to help decide priorities in the safety improvement of hazardous chemical plants. He consulted the Atomic Energy Authority who had experience in using numerical methods. They provided helpful advice on the application of such methods, including Fault Tree Analysis. Such analyses of hazards (HAZAN) facilitate the identification of those hazards that are acceptable and those that are intolerable. He soon recognised that if these techniques were applied to the “final” plant and process designs much protective equipment had to be added to reduce risks to acceptable levels. However, by applying the techniques to preliminary plant and process designs the need for such equipment could be markedly reduced by facilitating the design of inherently safer plants. Moreover, applying the techniques on the initial designs could save money.

In an article in the Chemical Engineer Claudia Flavell-White succinctly describes him in an article on “Chemical Engineers Who Changed the World” as, “A Lifetime Spent Saving Lives”. That is a perfect accolade, for a onetime chemist. Trevor left a huge legacy on ways for improving process safety. It is our responsibility to carry on his life’s work.

BASIL EDDERSHAW* & PETER BALL**

*Basil and Trevor were coworkers at ICI for many years and **Peter employed Trevor as a consultant at BNFL and worked with him on the odd committee.

This article was previous published in I.Chem.E’s Loss Prevention Bulletin, which was effectively started to cover some of Trevor’s early accident analyses for ICI.

Photograph pf Trevor Kletz kindly supplied from Peter Ball’s archives